New milling tip – easy and fast montage!

Klimas Wkręt-met introduced a new shape of the WKCP, WKCS, KMWHT screw milling tip.

Listening to the voice of experienced contractors, the Research and Development Department of Klimas Wkręt-met developed a modern shape of the milling tip of the WKCP, WKCS and KMWHT carpentry screws. Research and tests have shown a significant improvement in the screw assembly parameters, while maintaining its high strength parameters. The new tip means even FASTER INSTALLATION, RELIABLE STRENGTH and LESS RESISTANCE when screwing.

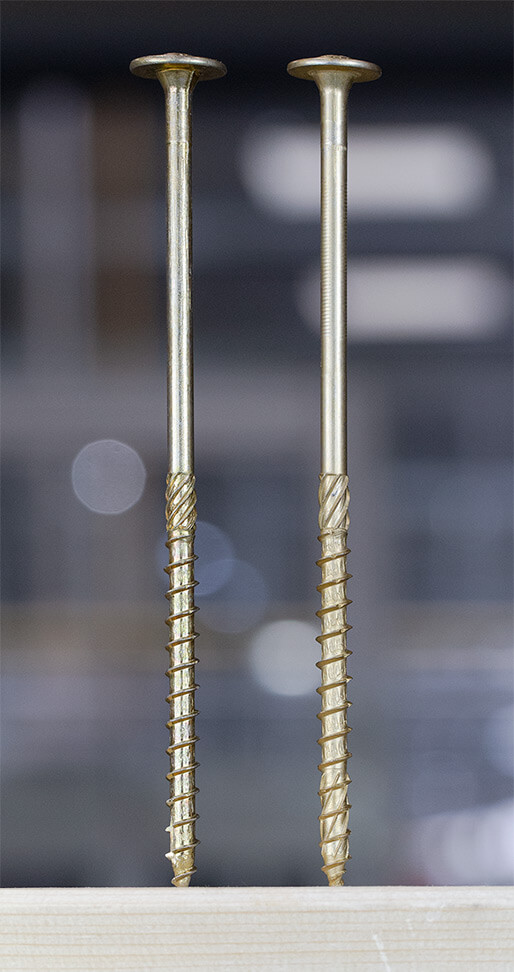

differences between the old and the new tip

OLD POINT

NEW POINT

DIFFERENCES BETWEEN THE OLD AND THE NEW TIP

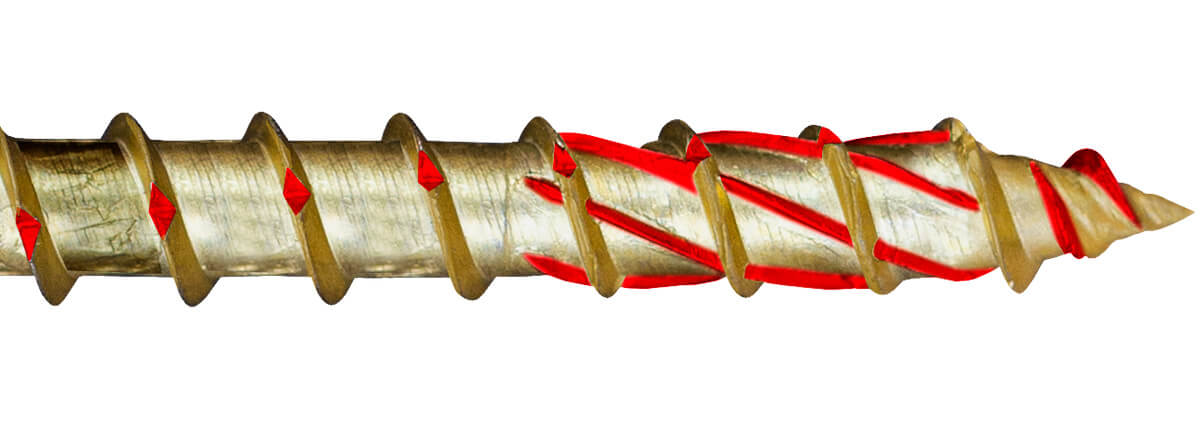

- MILLING TIP

Special design of the milling tip means up to 20% less refusal while the screw is advancing, which extends life of batteries and power tools themselves. - DOUBLE THREAD

Additional coils on the tip facilitate advancing – they allow the fixed wooden member to be joined faster with less pressure.. - SERRATED THREAD

Special cutting notches on the thread cut wood structural fibres while the screw is advancing. - WAX COATING

With a special wax coating the torque has been reduced significantly. This provides for faster and easier installation. Also, battery life of power tools is extended.

The double thread causes the same effect to be achieved with much less pressure.

The new shape of the screw tip reduces the screwing time by up to 40% with the same load.

The new shape of the milling tip allows you to achieve up to 20% less resistance when screwing. This parameter is particularly important for those specialists who use cordless tools on a daily basis – extension of battery life.

shorter screwing time

Tests performed before the product has been implemented showed that a new design of the screw tip provides for shortening of the screwing time by even 40% at the same load. Such saving depends on type of connection and the wood used.

double thread – quicker installation

Additional coils on the point allows for faster joining of the fixed wooden member at the first stage of the screw advancing. Such advantage is particularly important with connections where pressing on the screw is hindered. The double thread ensures obtaining the same effect with much lower pressure.

less refusal while screwing

The new design of milling tip reduces the refusal while screwing by up to 20%. This parameter is particularly relevant for such specialists who use power tools on a daily basis – as this extends the battery life.

high resistance parameters

Designed in cooperation with contractors, the new point of carpentry screws facilitates installation and features high resistance, i.e. pull-out resistance, shearing resistance, etc.

Products with new milling tip

SCREW MATERIAL AND OTHER TECHNICAL PARAMETERS REMAIN UNCHANGED

INCLUDED IN THE OFFER FROM 24.05.2021

Products will be replaced consecutively for screws with new milling tip once current stocks are out.

We also inform you that indices and bar codes of products remain the same.

Products with a new milling tip are marked as follows.

In case of any questions, please contact with our Customer Service or your consultant / ew. contact person.