product categories

we have solutions for you

knowledge zone

bestsellers

new products

news

Klimas Wkręt-met is a leading producer of the highest quality fastening technologie.

Klimas Wkręt-met is the largest Polish manufacturer of high quality fastening techniques: screws, nails, dowels, carpentry screws, roofing screws, chemical anchors and other fasteners.

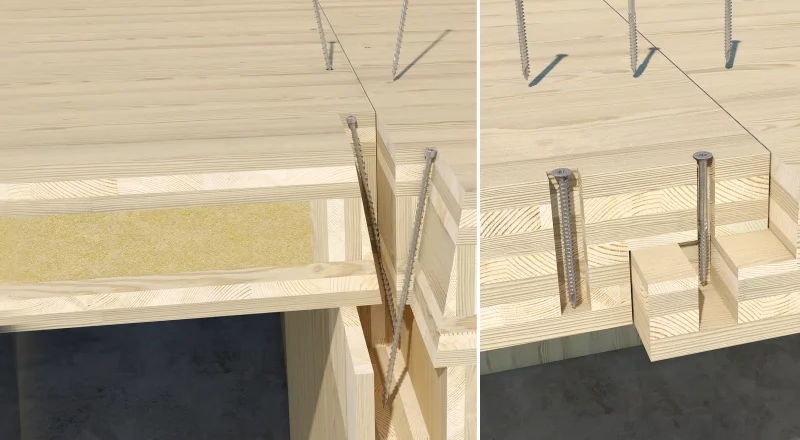

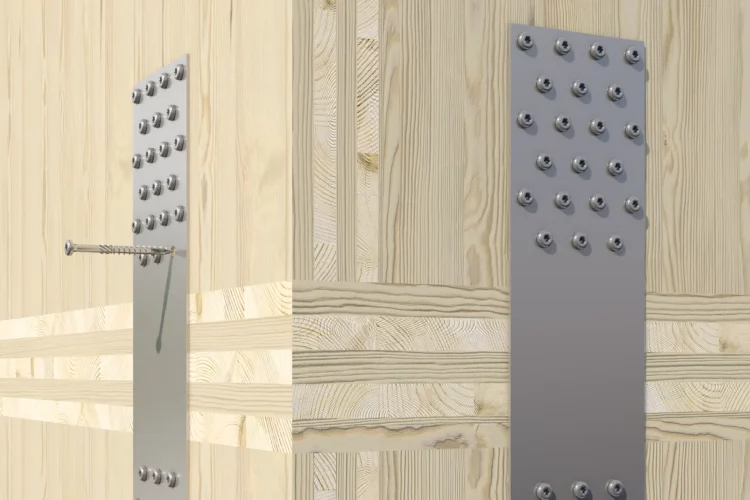

It has been setting standards in the field of fastening techniques for many years. The company offers, among others, screws for fixing in PVC elements, fasteners for mounting windows and doors, frame plugs, fasteners for thermal insulation, which are an essential element of passive houses, hardened and carpentry screws for wood, self-drilling and self-tapping screws for sheet metal and roofing, roofing screws, chemical anchors and mechanical, metric screws and wood screws, fixings for plasterboard technology.

Klimas Wkręt-met delivers its products to more than 60 countries.