Catalog Klimas Fastener Technologies

The new, updated Klimas Wkręt-met catalog includes our current full range of fastening products and a whole range of essential technical information. In the catalog you will find many new products like screws for concrete or wedge anchors.

You can view it in a convenient way on our website or download a PDF file with catalog and have it always at hand.

find the product you are interested in

- External thermal insulation composite system - ETICS

- Plugs for mineral wool insulation

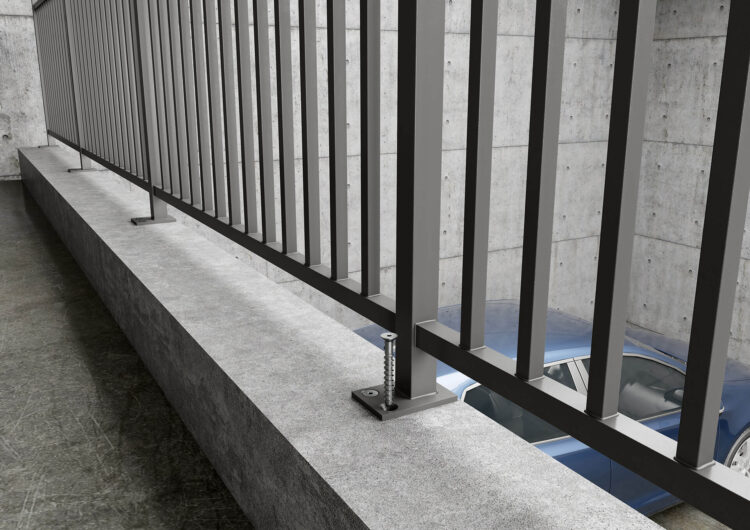

- Mechanical anchors, concrete screws, chemical anchors

- Chemical anchors

- Frame and general purpose fixings

- Wall plugs

- Hammer drive fixings

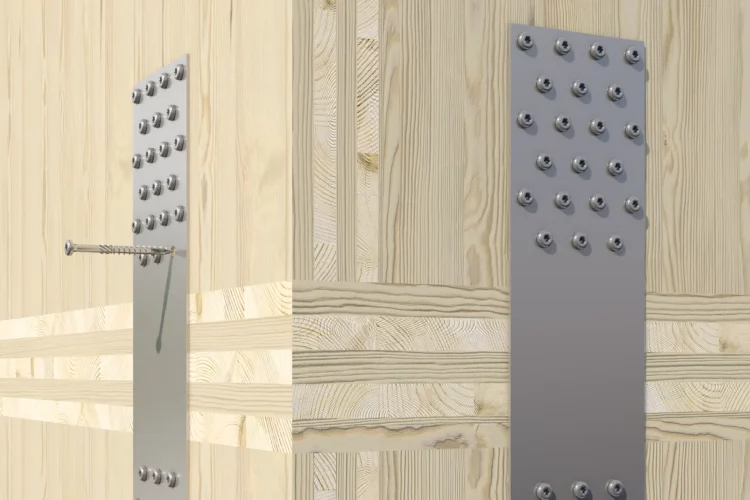

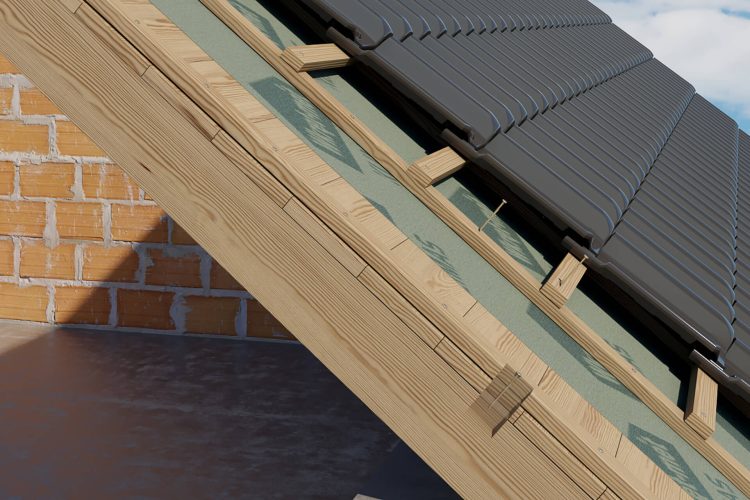

- Screws and fasteners for wooden constructions

- Carpentry joints

- Fastening systems for lightweight roof and wall cladding

- Fasteners for flat roof thermal insulation and waterproofing system

- Screws and fasteners for windows and doors

- Drywall fastener system

- Bolts and screws

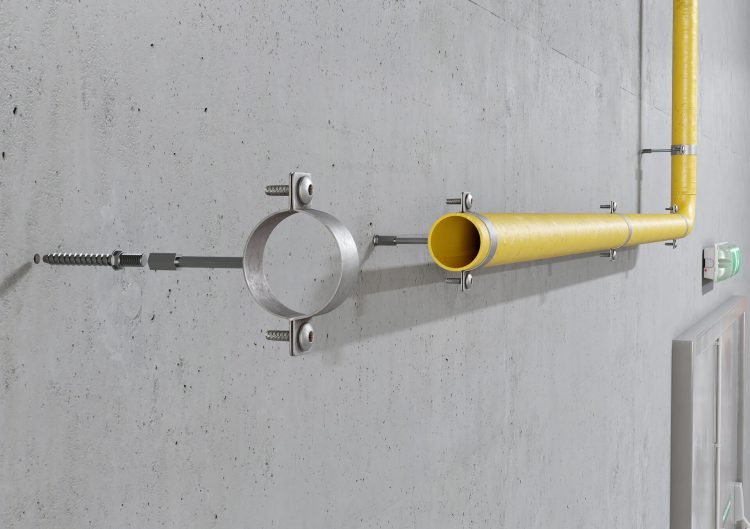

- Installation systems and sanitary fixings. Clamps and bands

- Electrical fasteners

- Construction chemical

- Power tool accessories

- Tapes and foils

see more

Washer head screw (TX)

WKCP

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No 140/SZ/19

Size: 366,84 KB

Product data sheet WKCP

Size: 410,14 KB

see more

Countersunk screws (TX)

WKCS

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No 141/SZ/19

Size: 148,02 KB

Product data sheet WKCS

Size: 374,65 KB

see more

Washer

PWKCS

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Product data sheet PWKCS

Size: 173,77 KB

see more

Countersunk screws (TX)

KMWHT

N

Download all

Declaration of performance No 124/SZ/17

Size: 248,75 KB

Product data sheet KMWHT

Size: 400,12 KB

see more

Screw for wooden constructions with full thread and pan head

WKFC

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No WKFC/21

Size: 392,96 KB

Product data sheet WKFC

Size: 287,22 KB

see more

Screw for wooden constructions with countersunk head

WKFS

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No WKFS/21

Size: 392,99 KB

Product data sheet WKFS

Size: 288,14 KB

see more

Screw for wooden constructions with double thread

WKPC

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Product data sheet WKPC

Size: 308,57 KB

see more

Spacer (distance) screw

WKSS

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No WKSS/21

Size: 395,69 KB

Product data sheet WKSS

Size: 365,16 KB

see more

Screws for angled timber connectors

WKLC

N

Download all

European Technical Assessment ETA-18_0817

Size: 1,95 MB

Declaration of performance No WKLC/21

Size: 395,76 KB

Product data sheet WKLC

Size: 314,46 KB

see more

Hex head wood screw

K

Download all

Declaration of performance No 126/SZ/17

Size: 249,42 KB

Product data sheet K

Size: 314,08 KB

see more

Countersunk screws (PZ)

KDH / KMH / BWK

Download all

Product data sheet KDH/KMH (non-full thread)

Size: 412,31 KB

Product data sheet KDH/KMH (full thread)

Size: 427,42 KB